The Importance of Balancing Industrial Rotors

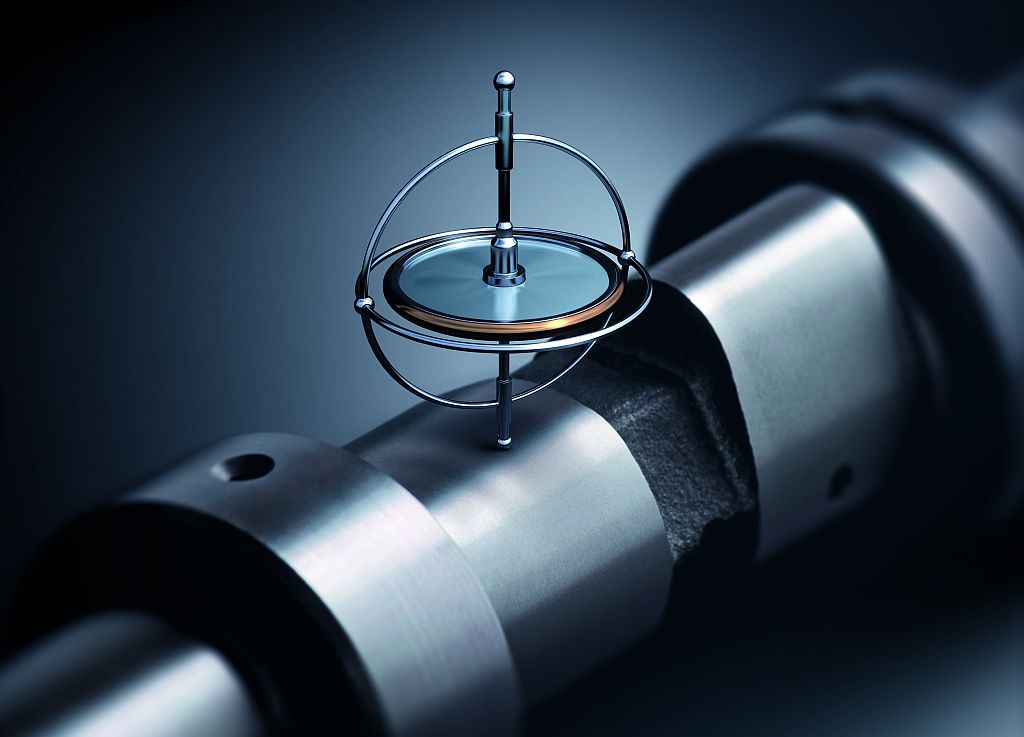

Industrial rotors are essential components used in various industrial machines. They carry rotating parts in machines such as pumps, spindle motors, fans, armatures, centrifugal pump motor shafts, cylinders, pulleys, compressor rotors, agricultural machine rotors, drums, helices, bells, separators, turbines, electric motors, and similar equipment, fulfilling their functions. However, improper balancing or imbalance of rotors can lead to serious problems. Therefore, the importance of balancing industrial rotors is significant.

What Is Balancing?

Balancing refers to minimizing vibrations when a rotor rotates. If a rotor is unbalanced, vibrations occur during rotation. These vibrations can be harmful to both the rotor itself and the machine or system to which the rotor is mounted. Balancing redistributes the weight distribution and rotary forces of the rotor, thus helping to prevent unwanted vibrations.

The Importance of Balancing

• Longer Lifespan: A balanced rotor results in less wear and tear, extending the lifespan of both the rotor and other connected parts. Vibrations caused by imbalance can lead to cracks, deformations, and even breakage of components.

• Higher Performance: A balanced rotor rotates more smoothly, leading to more efficient machine operation. Reduced vibration results in less energy loss and friction for the machine, translating to cost savings and higher productivity.

• Safety: Unbalanced rotors can pose hazards. High levels of vibration can damage the machine or cause accidents during operation. The vibrations caused by an unbalanced rotor can also pose health and safety risks to workers.

• Quality Control: Quality control is essential in industrial production. Unbalanced rotors can adversely affect product quality. For example, vibrations caused by an unbalanced rotor can lead to defects in manufactured products.

• Customer Satisfaction: Quality products and reliable machines increase customer satisfaction. Balanced rotors lead to fewer breakdowns and longer periods of trouble-free operation for machines, enhancing customer satisfaction and maintaining the company's reputation.

Balancing Process

Given the importance of balancing industrial rotors, the balancing process must be carried out correctly. This process typically involves the following steps:

• Evaluation of the Rotor: The condition of the rotor is assessed, and the need for balancing is determined.

• Testing with a Balancing Machine: The rotor is tested on special balancing machines, and the degree of imbalance is determined.

• Adding or Removing Weight: The balance of the rotor is adjusted, usually by adding or removing weight.

• Re-Testing: The rotor is re-tested after the balancing process, and vibration levels are checked.

• Approval and Certification: The rotor is certified to meet the specified standards, and necessary certification processes are completed.

The importance of balancing industrial rotors is significant for machine performance, safety, and product quality. Balanced rotors provide longer-lasting and more reliable machines. Therefore, it is essential for industrial facilities to regularly balance and maintain rotors, reducing operating costs and increasing efficiency.