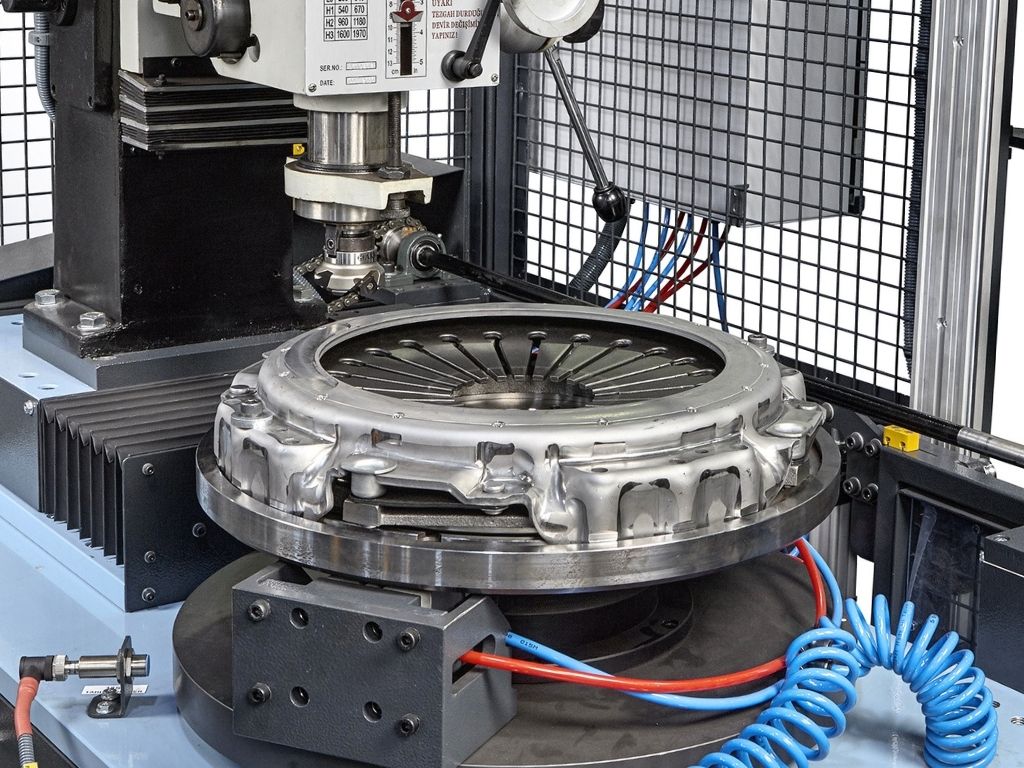

UF Series Vertical Balancing Machines

UF series universal vertical balancing machines are designed for balancing operations of various disc shaped rotors such as drum, brake disc, centrifugal pump, pump impeller, clutch components etc. with optional milling unit, unbalance correction can be performed manually. The milling unit can move at horizontal or vertical axis. During milling operation, the angular movement of the rotor is performed by a manual turn table unit. The milling unit can be used as a drilling unit with the suitable tool..

All over the balancing machine can be surrounded by switch controlled protection cage according to CE regulations. With the user-friendly software, the operation is very easy.

- Manual loading & unloading

- Manual pin system for centering with fixture

- Automatic unbalance measurement with high accuracy

- Automatic indexing to the correct position

- Manual or automatic clamping with collet system

- Unbalance correction with vertical milling unit

- Switch controlled protection cage according to CE regulations

- Swarf extractor

- Marking Unit

Technical Specifications

Downloads

Videos

More Information

| Technical Specifications | Unit | UF 50 | UF 100 |

| Maximum Rotor Weight (together with fixture) | Kg | 50 | 100 |

| Maximum Rotor Diameter | mm | 100 | 700 |

| Main Motor Power | kW | 1.5 | 7.5 |

| Centering - Clamping | - | Manual pin system for centering, with fixture | Manual pin system for centering, with fixture |

| Unbalance Measurement | - | Static - Dynamic | Static - Dynamic |

| Unbalance Correction Method | - | Vertical Milling - Horizontal Drilling | Vertical Milling - Horizontal Drilling |

| Balancing Speed (Measurable) (*) | rpm | 1500 | 1500 |

| Air Pressure | bar | 6 | 6 |